What Is a Pneumatic Drill

A pneumatic drill is an air powered tool that uses compressed air to spin a chuck or drive an impact mechanism. Compared with electric drills, a pneumatic drill delivers high power density, consistent torque, low heat buildup, and excellent duty cycle for continuous work.

Pneumatic drills are powerful tools that play a crucial role in various industries. These air-powered devices are commonly used to break through hard surfaces like concrete and stone, making them indispensable in construction, demolition, and industrial applications. Their ability to drill holes quickly and efficiently has made them a go-to choice for professionals working on projects that require precision and strength.

A pneumatic drill is commonly used in a wide range of tasks, from road maintenance to mining operations. Its versatility and pneumatic drill advantages make it an essential tool in many sectors. This article will explore the basic principles of pneumatic drills, their applications in construction and infrastructure, specialized industry uses, and important safety considerations. By understanding the diverse pneumatic drill uses, readers will gain insight into why these tools are so widely utilized across different fields.

Pneumatic Drill Basics

Operating principle

-

The trigger opens a valve that admits compressed air into a pneumatic rotary vane motor or a hammer mechanism.

-

Expanding air drives vanes inside an eccentric rotor which converts pressure energy into mechanical rotation.

-

Output torque reaches the gearbox and the chuck. In hammer types, air also actuates an internal striker that delivers rapid blows for concrete and stone.

Key components

-

Air inlet and valve, NPT threaded, seals rated for oil mist

-

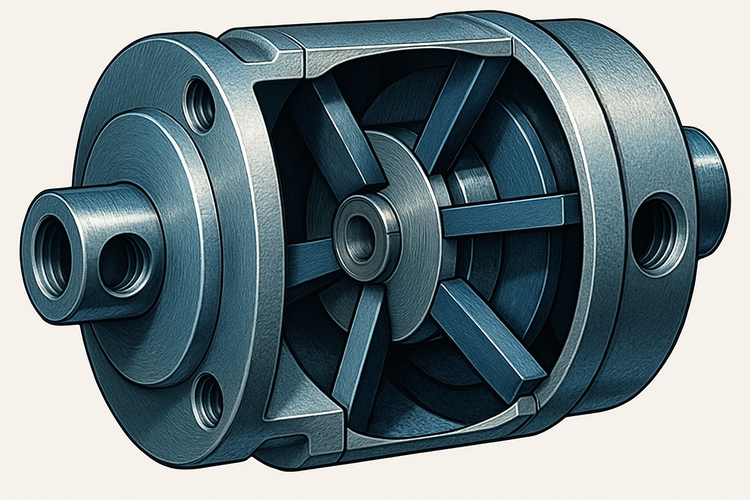

Rotary vane motor or percussion module

-

Planetary gearbox for torque multiplication

-

Chuck or collet, common are keyed 3-jaw chucks, Jacob taper, SDS for masonry

-

FRL connection downstream, filter, regulator, lubricator to protect the motor

-

Exhaust port with muffler to reduce noise and redirect air

-

Housing in aluminum or composite for strength with low mass

-

Ergonomic handle with anti-slip grip and two handed option for hammer work

Types of pneumatic drill

-

Rotary pneumatic drill for metals, plastics, composites

-

Reversible pneumatic drill for tapping and production lines

-

Angle pneumatic drill for tight spaces and jig fixtures

-

Hammer pneumatic drill for masonry and roadwork

Core Specs to Know Before You Buy

-

CFM at load, typical 4 to 20 CFM for handheld units

-

Rated PSI often 90 PSI at the tool inlet

-

Free speed RPM match to bit diameter and material

-

Max torque and stall torque for large diameter drilling

-

Noise level dBA at the operator position

-

Vibration value m/s² for HAVS control

-

Chuck capacity and spindle thread

-

Weight and length for fatigue and reach

-

Rule of thumb

For a handheld pneumatic drill, size the compressor to at least tool CFM × 1.5 to cover line losses and duty cycle. Maintain a steady 90 PSI at the tool, not only at the compressor outlet.

Construction and Infrastructure Applications

Building demolition and renovation

A pneumatic drill is commonly used in building demolition and renovation projects due to its powerful and precise nature. Its ability to pound through hard surfaces with controlled force makes it ideal for breaking down concrete walls, floors, and other structural elements. In demolition work, the drill's high power output allows for quick and efficient removal of materials, reducing project timelines and labor costs. During renovation, the pneumatic drill is used to create openings for new installations, such as windows or doorways, in existing structures. Its versatility in handling various materials, from concrete to stone, makes it an essential tool for contractors working on both small-scale home renovations and large commercial building projects.

Highway and bridge construction

In highway and bridge construction, pneumatic drills play a crucial role in several aspects of the work. They are frequently employed to break up existing asphalt or concrete surfaces during road maintenance or expansion projects. The drill's strength and efficiency in this task help minimize road closure times and reduce disruption to traffic flow. For bridge construction, pneumatic drills are used to create holes for foundation work and to install support structures. Their ability to operate in challenging environments, including underwater conditions, makes them invaluable for tasks such as drilling into riverbeds or other submerged surfaces during bridge construction.

Utility installation and repair

Pneumatic drills are essential tools for utility installation and repair work. They are commonly used to dig holes for signposts, create openings for underground utility lines, and break through pavement to access buried pipes or cables. The drill's power and precision allow workers to quickly and accurately create the necessary openings while minimizing damage to surrounding areas. In urban environments, where space is often limited and existing infrastructure must be navigated carefully, the pneumatic drill's controllability is particularly advantageous. Its ability to operate in various weather conditions and its reliability in demanding work environments make it a preferred choice for utility companies and contractors engaged in infrastructure maintenance and expansion projects.

Specialized Industry Uses

Automotive and metalworking

A pneumatic drill is commonly used in automotive manufacturing for various applications. These powerful tools play a crucial role in drilling holes for transmission shafts, engine blocks, air bag propellant chambers, and camshafts. The efficiency of pneumatic drills is essential in automotive production lines, where every minute counts. Manufacturers are constantly seeking innovative tooling improvements to enhance drilling efficiency and reduce costs. In metalworking, pneumatic drills are utilized for tasks such as cutting, drilling, and polishing. Their versatility and power make them indispensable in metal fabrication processes, contributing to increased productivity and precision.

Shipbuilding and marine applications

In the shipbuilding industry, pneumatic drills are essential for heavy-duty tasks like cutting, drilling, fastening, and welding. These tools are designed to withstand the harsh conditions of shipyards, including exposure to saltwater and humidity. Pneumatic drills are particularly useful for drilling holes and fastening components during ship construction. They also play a vital role in surface preparation, with pneumatic sanders ensuring even coatings and improving vessel longevity. The durability and precision of pneumatic tools make them invaluable in the demanding environment of shipyards.

Aerospace industry utilization

The aerospace industry relies heavily on pneumatic drills for manufacturing aircraft components. Approximately 25% of all drilled holes in aircraft manufacturing are done manually using these tools. Pneumatic drills are preferred in aerospace applications due to their power, reliability, and ability to maintain consistent torque and speed. They are particularly useful in drilling holes in advanced materials like aluminum, titanium, and composite stacks, and performing precision work on critical components. The aerospace industry's demanding nature requires pneumatic tools that can withstand rigorous production use while maintaining accuracy and efficiency. Low mass housings improve ergonomics during extended overhead work. Tight runout control and accurate RPM protect hole quality and fastener integrity.

Selection Guide, Match the Pneumatic Drill to the Job

Matrix for common choices

-

Metal up to 6 mm: high RPM 2,500 to 4,000, 3 jaw chuck, 4 to 6 CFM

-

Metal 6 to 12 mm: mid RPM 1,200 to 2,500, more torque, 6 to 10 CFM

-

Metal 12 to 20 mm: low RPM 500 to 1,200, high torque, 10 to 15 CFM

-

Masonry: hammer type, SDS shank, 8 to 16 CFM

-

Tight spaces: angle head 90°, 1,800 to 3,000 RPM, 4 to 8 CFM

Bit guidance

-

HSS or cobalt for steel, carbide for hard alloys

-

Split point to reduce walking, use cutting oil

-

For composites, brad point or special PCD designed bits with vacuum extraction

Air System Setup for a Pneumatic Drill

Compressor sizing

-

Determine tool CFM at 90 PSI.

-

Compressor free air delivery should be 1.5 times tool CFM minimum.

-

Include diversity if multiple air tools run together.

Hose and fittings

-

Keep hose short and large in diameter to reduce pressure drop.

-

1 to 5 m is ideal for hand tools.

-

Use 3/8 in ID hose for up to 10 CFM, 1/2 in ID for 10 to 20 CFM.

-

Quick couplers should match hose ID and flow class.

FRL care

-

Filter at 5 to 40 microns, regulator set to 90 PSI at the tool, lubricator at 2 to 3 drops per minute during continuous use.

-

Check the air inlet screen and muffler monthly.

Safety Practices for a Pneumatic Drill

-

Wear safety glasses, face shield for masonry, hearing protection, gloves, and safety shoes.

-

Secure workpieces, avoid loose clothing and jewelry.

-

Do not carry the pneumatic drill by its hose.

-

Bleed air pressure and lockout before changing bits or chucks.

-

Manage hoses to prevent trips and whipping.

-

Follow scheduled vibration exposure breaks and use anti-vibration handles when available.

Maintenance Checklist

-

Daily, drain water from FRL bowl and verify oil feed

-

Weekly, inspect hoses for cuts and bulges, replace if damaged

-

Monthly, check chuck jaws and spindle runout, check gearbox grease if applicable

-

Quarterly, measure free speed RPM and compare with nameplate

-

Record torque, vibration, and noise measurements for trend monitoring

FAQs about Pneumatic Drills

1. What CFM do I need for a pneumatic drill

Most handheld models need 4 to 12 CFM at 90 PSI. Heavy duty and hammer types can require 12 to 20 CFM. Size the compressor to 1.5 times the total CFM of tools that will run at the same time.

2. What RPM should I use

Use higher RPM for small bits and softer materials, lower RPM and higher torque for larger bits. Confirm the bit maker’s recommended surface speed.

3. How do I reduce noise

Use a muffler, keep the exhaust pointed away, maintain lubrication, and check bearings. A healthy pneumatic drill is quieter and more efficient.

4. Why is my pneumatic drill losing power

Common causes are pressure drop from long small hoses, clogged filters, dry motor vanes, or low compressor capacity. Verify 90 PSI at the tool while running.

Soartec provides various models and types of pneumatic drills. Click here to learn more.