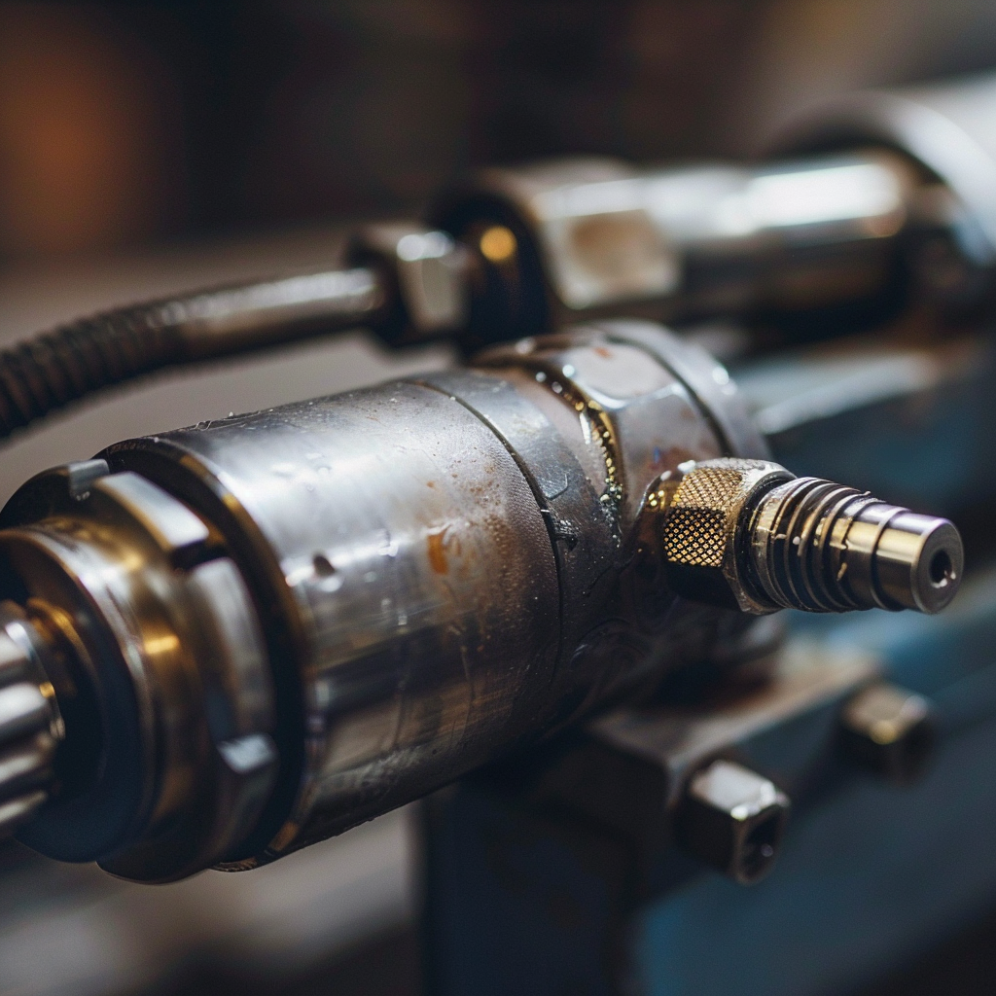

Introduction: The Imperative of Accurate Pressure Measurement in Pneumatic Tools

In the realm of pneumatic tools, precision in pressure measurement, particularly when it comes to air pressure conversions, is paramount for ensuring both optimal performance and safety. This guide underscores the importance of accurate pressure measurement and unit conversions, especially converting from bar to pounds per square inch (PSI). Maintaining accuracy in these conversions is crucial for preventing tool malfunctions and ensuring compliance with safety and performance standards.

Understanding Pressure Units: Bar vs. PSI

Bar and PSI are the primary units for pressure measurement in pneumatic systems. One bar, approximately equal to atmospheric pressure at sea level, is scientifically defined as 100 kilopascals (kPa), which equates to roughly 14.5038 PSI. Other common pressure units include pascals (Pa), megapascals (MPa), millimeters of mercury (mmHg), torr, and dynes/cm2. Understanding these units and mastering air pressure conversions using a reliable pressure converter or pressure unit converter is essential for technicians and operators to effectively manage their pneumatic tools, ensuring precise control over their operations and preventing equipment damage.

Converting 6.3 Bar to PSI: A Step-by-Step Guide

One of the most common tasks when working with pneumatic tools is converting bar to PSI. For example, to convert 6.3 bar to PSI:

6.3 × 14.5038 = 91.374 PSI

This conversion is an excellent example of why air pressure conversions are so important for setting tools to the correct operating pressure, ensuring both functionality and safety. A pressure conversion table or pressure conversion chart can be helpful for quick reference when converting between various pressure units of measurement.

The Importance of Correct Pressure Settings in Pneumatic Tools

Proper pressure settings play a pivotal role in the safe and efficient operation of pneumatic tools. The impact of pressure is significant, influencing the tools’ performance, durability, and user safety. Pressure is defined as force per unit area, typically measured in pascals (Pa), where one pascal equals one newton of force applied over an area of one square meter. Ensuring that tools are accurately set and maintained with the right pressure settings—including frequent air pressure conversions—helps guarantee optimal performance and longevity within operational limits. For guidance on selecting the right pneumatic tools, check out our comprehensive guide on choosing the top 3/4-inch air impact wrench for your workshop.

Essential Tools for Accurate Pressure Measurement

In the world of pneumatic tools, having quick and accurate air pressure conversions at your fingertips is critical. Tools such as digital calculators, mobile applications, and detailed conversion charts are indispensable for determining the correct PSI for air tools. A pressure conversion calculator can easily convert pressure from units like kPa to psi to bar, or even less common units like kg/cm2 or mbar. Additionally, understanding the SCFM (Standard Cubic Feet per Minute) requirements for air tools ensures that tools are running efficiently and within their specified pressure parameters. An scfh to psi calculator can be helpful for determining air flow requirements.

Maintaining Tool Accuracy with Reliable Pressure Measurement Tools

Regular checks and calibration of pressure gauges are necessary to ensure the accuracy of pneumatic tools, especially when converting between bar and PSI. Utilizing reliable measurement devices like pneumatic pressure testers is crucial for verifying tool pressure. Consistent use of these tools, alongside accurate air pressure conversions, helps prolong the life of your equipment and ensures it operates within safe limits. A pascal conversion or atm conversion chart can assist with calibrating pressure measurement tools to various units.

Avoiding Common Conversion Errors in Pneumatic Settings

Errors in air pressure conversions can lead to a variety of operational issues, including tool damage and safety hazards. It’s essential to double-check conversion calculations, especially when switching between bar and PSI or less familiar units like torr or dynes/cm2, to maintain the integrity and safety of pneumatic tools. Utilizing standardized conversion charts, reliable calculators, and regular calibration of instruments helps mitigate these risks.

Advanced Learning: Enhancing Expertise in Pneumatic Pressure Dynamics

For those seeking to deepen their expertise in pneumatic pressure dynamics, there are ample educational resources available. Workshops, webinars, and specialized courses can provide further insights into topics such as air tool CFM requirements, advanced air pressure conversions, and the relationships between pressure, force, and area. Expanding your knowledge in these areas ensures better tool management and operational excellence.

Conclusion: Mastering Pressure Conversions for Optimal Tool Performance and Safety

Mastering air pressure conversions is more than a technical necessity—it’s key to ensuring the safe and efficient operation of pneumatic tools. Accurate pressure measurements, whether in bar, PSI, Pa, or other units, guarantee that your tools are running at their best while minimizing risks of accidents or malfunction. This guide provides essential knowledge to effectively manage pneumatic tools, highlighting the critical importance of safety, operational efficiency, and mastering pressure dynamics.

For more product insights and tools to support your operations, Soartectools is here to assist you in achieving precision and safety in all your pneumatic tasks. Tap to learn more our product.