Introduction

Air Motor, also known as pneumatic motors, play a crucial role in powering various pneumatic tools. These motors utilize compressed air to generate mechanical movement, making them ideal for high-performance industrial and commercial applications. Unlike electric motors, Air Motor offer distinct advantages such as durability, quick start-up, and safety in hazardous environments. In this blog, we will explore the working principles, advantages, applications, and key design factors that enhance Air Motor performance for pneumatic tools.

How Do Air Motor Work?

Air Motor operate by converting compressed air energy into mechanical motion. This is achieved through high and low-pressure variations in airflow that drive internal components such as pistons or vanes. There are two main types of Air Motor:

- Piston-Type Air Motor: These motors use the reciprocating motion of pistons inside a cylinder to create linear or rotational movement. They are commonly found in heavy-duty pneumatic tools requiring high torque.

- Vane-Type Air Motor: These motors use airflow to push internal vanes, generating continuous rotation. The speed of a vane motor is inversely proportional to torque, and air consumption increases with speed.

Advantages of Air Motor in Pneumatic Tools

Air Motor provide several advantages over electric motors, making them ideal for industrial and workshop applications:

- Simple and Durable: With a robust structure and fewer electrical components, Air Motor require minimal maintenance and withstand harsh environments.

- Fast Response and Start-Up: Air Motor reach operating speed almost instantly, making them highly responsive for applications that require rapid actuation.

- Enhanced Safety: Since Air Motor rely on compressed air rather than electricity, they eliminate risks of electrical fire or explosion, making them suitable for hazardous environments.

- High-Frequency Operation: Unlike electric motors, Air Motor do not overheat under continuous operation, maintaining efficiency even under high-frequency usage.

- Cost-Effective for High-Torque Applications: Efficient Air Motor provide lower long-term operating costs compared to electric motors in high-torque applications.

Challenges and Limitations of Air Motor

Despite their advantages, Air Motor also have some limitations:

- Lower Energy Efficiency: Air Motor have lower energy conversion efficiency compared to electric motors, leading to higher energy consumption.

- Dependence on a Compressed Air Supply: A stable and efficient air source is necessary for consistent performance.

- Complex Control System: Regulating airflow and pressure requires precision to ensure stable operation, making control more intricate compared to electric motors.

Applications of Air Motor in Pneumatic Tools

Air Motor are widely used in various pneumatic tools and industrial applications, including:

- Industrial Automation: Common in robotic arms, automated assembly lines, and conveyor systems.

- Pneumatic Power Tools: Used in high-performance tools like air impact wrenches, air grinders, air drills, and air sanders.

- Material Handling & Transport Systems: Found in pneumatic lifts, conveyors, and air-powered winches.

Optimizing Air Motor Performance in Pneumatic Tools

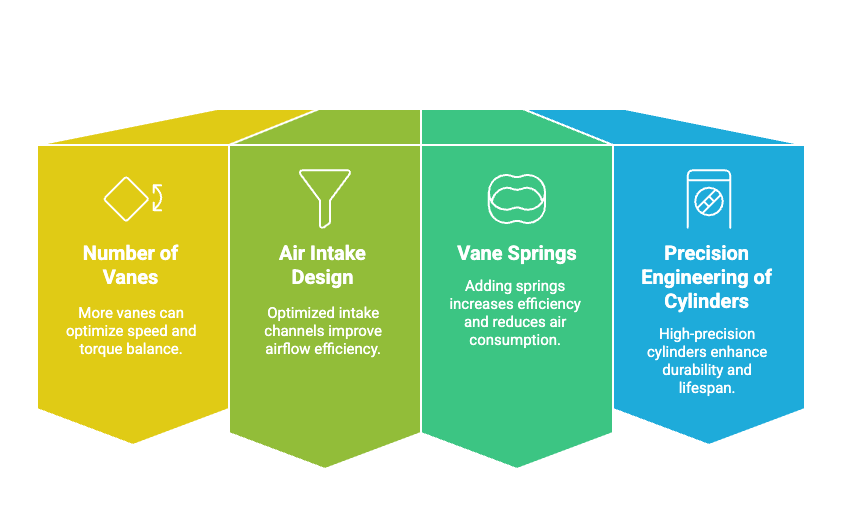

Several design factors influence the efficiency and effectiveness of Air Motor in pneumatic tools:

- Number of Vanes: More vanes can optimize speed and torque balance.

- Air Intake Design: Optimized intake channels improve airflow efficiency.

- Vane Springs: Adding springs increases efficiency and reduces air consumption.

- Precision Engineering of Cylinders: High-precision cylinders enhance durability and lifespan.

Conclusion

Air Motor are an essential component in pneumatic tools, providing unmatched durability, safety, and performance. While they require a stable compressed air supply and efficient control mechanisms, their benefits outweigh these challenges in high-intensity industrial applications. By optimizing design factors, manufacturers can further enhance Air Motor efficiency, making them even more valuable for pneumatic tool users worldwide.

For professionals and businesses seeking high-performance pneumatic tools, understanding Air Motor is key to choosing the right equipment for efficiency and longevity. If you’re looking for precision-engineered pneumatic tools, explore our range at Soartec Tools.