Defining the Air Impact Wrench and Its Core Mechanism

An air impact wrench, also known as a rattle gun, air impact gun, or air wrench, is a high-torque power tool designed for demanding fastening tasks. To understand what an impact wrench is, let’s explore the air impact wrench definition and its purpose. An air impact wrench operates by storing energy in a rotating mass and then releasing it to the output shaft, making tough jobs easier and reducing user strain. This article will delve into what an air impact wrench is used for and how it differs from other similar tools.

Essential Components

- Motor: Powers the hammer mechanism

- Hammer mechanism: Rotates and impacts the anvil

- Anvil: Produces high-torque forces

- Output shaft: Transfers torque to fasteners

- Trigger: Activates the motor

- Reverse switch: Changes output direction

Torque Generation in Air Impact Wrench

Understanding how an air impact wrench works is crucial to appreciating its effectiveness. The motor spins the hammer mechanism rapidly. As torque demand increases, the hammer binds and strikes the anvil, creating high-torque impacts. This process explains how an impact wrench works to generate the necessary force for tough fastening jobs.

Air Impact wrenches are versatile tools used for loosening and tightening bolts in various industries. They’re employed in automotive workshops, construction sites, and other professional settings where powerful rotational force is needed. The pneumatic impact wrench purpose is to handle challenging fastening tasks efficiently, making it indispensable for professionals who require precision and power in their work.

Types of Impact Wrench

Impact wrenches, also known as power wrenches, come in various types, each designed for specific applications:

Air Impact Wrench

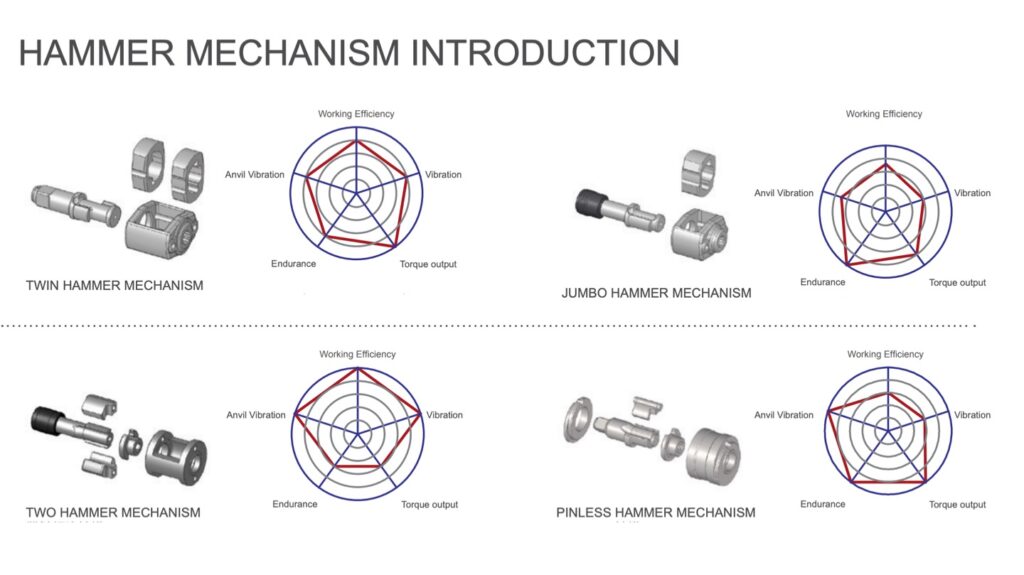

Also called pneumatic impact wrenches, these tools run on compressed air. They’re popular in auto shops due to their high torque output, durability, and consistent performance. While they require an air compressor, limiting portability, they provide steady power for extended use. Drive sizes range from 1/2” to 1-1/2”, ½ “ and 3/4” being common. Larger drives can generate up to 3,000 ft/lbs of torque. Various hammer mechanisms are used in air impact wrenches, such as:

- Twin hammer delivers higher torque efficiently

- Jumbo hammer generates extreme power for heavy-duty jobs.

- Two-hammer designs are more common for general-purpose use.

- Pinless hammer offers enhanced durability in harsh environments with fewer moving parts.

Electric Impact Wrench

Electric impact wrenches come in corded and cordless models. Corded versions offer consistent power but are less common now. Cordless models, using 18-28 volt rechargeable batteries (NiMH, NiCad, or Li-Ion), are popular for their portability, making them ideal for on-site repairs or locations without direct power access. These battery-powered tools often feature an electric motor that provides impressive working torque for various applications.

Hydraulic Impact Wrench

Hydraulic impact wrenches excel in heavy-duty industrial tasks requiring extreme torque. Using hydraulic fluid for power, they offer a high power-to-weight ratio. These tools are ideal for construction and industrial settings demanding maximum torque output.

With adjustable impact intensity and torque ranging from 500 to 2,500 ft./lbs., hydraulic impact wrenches are powerful but expensive and bulky, making them less suitable for everyday use.

Air Impact Wrench Industrial Applications

Automotive Industry

Air impact wrenches, including air guns for tires, are crucial in automotive repair. They quickly remove and install lug nuts, reducing service time. These tools are also vital for suspension work and engine repairs, where high nut-busting torque is necessary.

Air Impact Wrench: Revolutionizing Fastening in Construction and Manufacturing

Air impact wrenches are essential in construction and manufacturing for enhancing efficiency. These tools rapidly tighten bolts and fasteners, reducing assembly time. They’re crucial for heavy equipment assembly and maintenance, machine tool production, and major construction projects. In product assembly lines, impact wrenches significantly speed up the process while ensuring consistent torque application.

Heavy Equipment Maintenance

Air impact wrenches are vital for heavy machinery upkeep. They service industrial motors, gearboxes, and components of large vehicles like skid steers and forklifts. Their high torque output is ideal for loosening rusted or over-tightened fasteners. In mining and oil and gas sectors, these tools facilitate machinery assembly and disassembly, ensuring operational safety and efficiency. Cordless impact wrenches are particularly useful for on-site repairs in remote locations.

Drive Sizes of Air Impact Wrench

Air impact wrenches come in various drive sizes, each tailored to specific tasks. The most common sizes include 1/4″, 3/8″, 1/2″, 3/4″ and larger options like 1″ and 1-1/2″. Smaller drives, such as 1/2″ and 3/4″, are ideal for light-duty applications, including automotive maintenance and assembly tasks. In contrast, larger drive sizes, like 1″ and 1-1/2″, provide the high torque necessary for heavy duty industrial work, such as assembling large machinery and equipment in construction and manufacturing settings.

For further details, you can read the full article of how to choose your own 3/4″ impact wrench and the features of 1/2″ impact wrench.

Conclusion

Impact wrenches have transformed how professionals handle challenging fastening jobs. Their high torque delivery with minimal effort makes them indispensable for tasks from changing tires to assembling heavy machinery. As technology advances, we can expect further improvements in impact wrench design and capabilities.

When choosing the right air impact wrench for your needs, it’s important to consider both the tool’s capabilities and its inner workings. Whether you’re wondering if the 3/8″ air impact wrench is essential for your toolkit or diving deeper into the parts diagram of a 1/2″ model, understanding how these tools operate will help you make an informed decision. For more demanding tasks, learning how to select the best 3/4″ wrench for your workshop and comparing 1″ air impact guns for industrial strength ensures you pick the perfect model for both precision and power.

Explore Soartectools’ industry-leading impact wrench range.

Air Impact Wrench 3/4″ | WS-2066 Series

- Std. Bolt Cap: 1-1/8″

- Square Drive: 3/4″

- Free Speed: 7500 rpm

- Air Cons: 600 L/min

- Air Inlet: 3/8″ PT

- Min. Hose Size: 1/2″

- Air Pressure: 90 psi (6.2 bar)

- Noise: 95.3 db(A)

-

Air Compact Impact Wrench 1/2″ with Protective Cover | WS-217 Series

Air Compact Impact Wrench 1/2″ with Protective Cover | WS-217 Series -

Air Composite Impact Wrench 1″ Twin Hammer | WX-21078

Air Composite Impact Wrench 1″ Twin Hammer | WX-21078 -

Air Impact Wrench 1/2″ Jumbo Hammer | WS-305JW1

Air Impact Wrench 1/2″ Jumbo Hammer | WS-305JW1 -

Air Impact Wrench 1/2″ Two Hammer | WS-2055/ WS-208D

Air Impact Wrench 1/2″ Two Hammer | WS-2055/ WS-208D -

Air Impact Wrench 1/2″ WS-208 Series

Air Impact Wrench 1/2″ WS-208 Series -

Air Impact Wrench 3/4″ | WS-2066 Series

Air Impact Wrench 3/4″ | WS-2066 Series -

Air Impact Wrench 3/4″ Twin Hammer | WS-2076/2086 Series

Air Impact Wrench 3/4″ Twin Hammer | WS-2076/2086 Series

FAQs

What is an impact wrench used for?

An impact wrench is specifically designed to drive long screws and bolts into tough materials efficiently. Common impact wrench uses include deck building, framing, cabinetry, and automotive work. The use of an impact wrench allows you to tackle demanding fastening jobs with ease, as it provides bursts of high torque to overcome resistance without stripping the fastener or damaging the material.

When to Use Impact Driver vs Drill?

Driver vs Drill: In the driver vs drill debate, it’s essential to understand their strengths and weaknesses. A drill is a versatile tool that excels at drilling holes and can handle light fastening tasks. An impact driver, on the other hand, is a specialized tool designed for driving screws and bolts with high torque. It’s not suitable for drilling due to its impact mechanism.

Hammer Drill: A hammer drill is another type of drill that combines rotational force with a hammering action. It’s designed for drilling into hard materials like concrete and masonry. While it shares some similarities with impact drivers, a hammer drill is not designed for driving fasteners and should not be confused with an impact driver.

Impact Wrench vs Impact Driver

When considering an air impact wrench vs air impact driver, it’s important to note their differences. An air impact wrench is generally more powerful and designed for heavy-duty fastening tasks, often used with socket wrenches for nuts and bolts. An impact driver, while also delivering rotational force with impacts, is typically smaller and used for driving screws and smaller bolts. The difference between impact driver and impact wrench lies in their size, power output, and intended applications.

Impact Wrench vs Impact Drill

In the impact wrench vs impact drill comparison, the key difference is their primary function. An impact wrench is specifically designed for tightening and loosening nuts and bolts, while an impact drill (which is often confused with an impact driver) is primarily used for drilling holes with the added benefit of an impact mechanism for tougher materials.

Additional Features

Many modern impact wrenches come with additional features to enhance their functionality:

- Torque control settings allow users to adjust the tool’s power output for different applications.

- Inline and pistol grip designs offer versatility for different working positions and spaces.

- Some models include LED lights for improved visibility in low-light conditions.

Understanding these differences and features helps in selecting the right tool for specific tasks, ensuring efficiency and effectiveness in various applications.