Introduction of Air Impact Wrenches

Air impact wrenches are essential tools in industries ranging from automotive repair to heavy machinery maintenance and industrial assembly. One of the most critical components of an impact wrench is its hammer mechanism, which determines how the tool delivers torque, its efficiency, durability, and suitability for different applications.

As an air tool manufacturer, we strive to provide high-performance air impact wrenches tailored to diverse industrial needs. In this blog, we’ll explore the different types of hammer mechanisms used in air impact wrenches, their applications, and how to select the right one for your specific tasks.

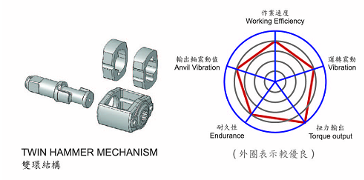

1. Twin Hammer Mechanism

Key Features:

✅ Ideal for quick disassembly of hard-joint nuts.

✅ Provides high torque for tightening and loosening hard-joint nuts.

✅ Stable vibration performance.

❌ Not suitable for soft-joint applications.

Application:

The Twin Hammer mechanism is widely used in high-torque applications requiring hard-joint nut tightening or removal. It distributes impact forces efficiently, converting them into strong rotational torque. This results in fast and effective performance in demanding environments such as automotive repair, heavy machinery, and industrial assembly.

Advantages:

✔ High torque transmission ensures efficient operation.

✔ Stable vibration control enhances operator comfort.

✔ Ideal for high-load environments with frequent use.

Limitations:

⛔ Only suitable for hard-joint applications—not recommended for soft-joint nuts, as excessive force may cause material damage.

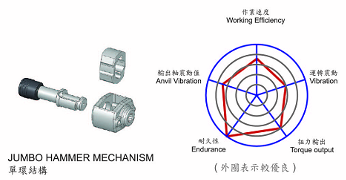

2. Jumbo Hammer Mechanism for Air Impact Wrenches

Key Features:

✅ Long service life.

✅ Suitable for quick disassembly of hard-joint nuts.

✅ Strong torque transmission for heavy-duty applications.

❌ Higher vibration levels than the Twin Hammer mechanism.

❌ Not suitable for soft-joint nuts.

Application:

The Jumbo Hammer mechanism is a simple yet powerful design, commonly used in high-torque impact wrenches for fast hard-joint nut removal. Due to its robust construction, it offers extended service life and is well-suited for demanding industrial settings.

Advantages:

✔ Durable and long-lasting.

✔ Strong impact force for hard-joint applications.

✔ Simple design reduces maintenance requirements.

Limitations:

⛔ Higher vibration levels may lead to operator discomfort during prolonged use.

⛔ Limited suitability for soft-joint applications.

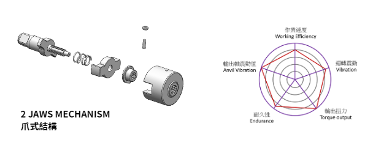

3. Two-Jaws Mechanism for Air Impact Wrenches

Key Features:

✅ Provides high and stable torque output.

✅ Ideal for production-line nut assembly.

✅ Works with both soft-joint and hard-joint nuts.

✅ Stable vibration performance.

Application:

The Two-Jaws mechanism is designed for precision assembly, making it ideal for production lines where consistent torque output is essential. It is widely used in industrial manufacturing to ensure controlled tightening of nuts without damaging materials.

Advantages:

✔ Suitable for both soft-joint and hard-joint nuts, providing greater versatility.

✔ Balanced and stable torque output ensures precision assembly.

✔ Reduced vibration enhances operator comfort.

Limitations:

⛔ Less impact force compared to Twin Hammer or Jumbo Hammer mechanisms.

⛔ More complex design may require specialized maintenance.

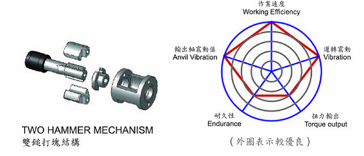

4. Two Hammer / Two Dog Mechanism

Key Features:

✅ Designed for fast assembly and efficient striking.

✅ Delivers consistent torque output.

✅ Works with both soft-joint and hard-joint nuts.

❌ Not suitable for high-pressure air supply, as excessive force may damage internal components.

Application:

This mechanism is optimized for high-speed assembly and industrial maintenance. It delivers smooth and controlled torque, making it ideal for environments requiring fast and repetitive nut tightening.

Advantages:

✔ High-speed performance improves assembly efficiency.

✔ Consistent torque output ensures stable fastening results.

✔ Compatible with both soft-joint and hard-joint applications.

Limitations:

⛔ Cannot be used with high-pressure air supply, as it may damage internal parts.

⛔ May require careful operational settings to maximize durability.

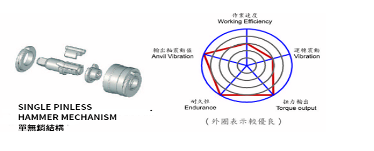

5. Single Pinless Hammer Mechanism

Key Features:

✅ Provides high torque output for nut tightening and removal.

✅ Suitable for both soft-joint and hard-joint applications.

✅ Long service life due to simple, durable design.

❌ Higher vibration levels due to single-side impact.

Application:

The Single Pinless Hammer mechanism is designed for high-torque tasks while maintaining a simplified design for durability. It is suitable for a wide range of industrial applications, including construction, maintenance, and heavy machinery work.

Advantages:

✔ Strong torque performance for various applications.

✔ Simple structure increases longevity and durability.

✔ Suitable for both soft and hard joints.

Limitations:

⛔ Generates higher vibration, potentially leading to operator fatigue.

⛔ May require additional vibration-reducing accessories.

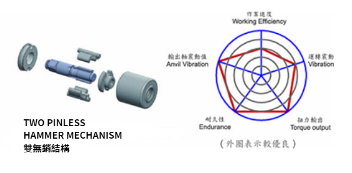

6. Two Pinless Hammer Mechanism

Key Features:

✅ High torque output for nut tightening and removal.

✅ Compatible with both soft-joint and hard-joint applications.

✅ More balanced vibration due to dual-sided impact.

✅ Enhanced durability with a long-lasting transmission shaft.

Application:

The Two Pinless Hammer mechanism is designed to offer strong and balanced performance, making it a highly durable choice for industrial assembly, automotive repair, and heavy-duty applications.

Advantages:

✔ Delivers high and stable torque output.

✔ Less vibration compared to the Single Pinless Hammer mechanism.

✔ Excellent durability, reducing the need for frequent replacements.

Limitations:

⛔ Slightly heavier design due to increased durability.

⛔ More complex internal structure compared to simpler hammer mechanisms.

Conclusion: Choosing the Right Hammer Mechanism

Selecting the right hammer mechanism in air impact wrenches depends on your application’s specific requirements. Here’s a quick guide:

| Mechanism Type | Hard-Joint Applications | Soft-Joint Applications | High Torque | Low Vibration | Long Service Life | High-Speed Assembly |

| Twin Hammer | ✅ Yes | ❌ No | ✅ Yes | ✅ Yes | ✅ Yes | ❌ No |

| Jumbo Hammer | ✅ Yes | ❌ No | ✅ Yes | ❌ No | ✅ Yes | ❌ No |

| Two-Jaws | ✅ Yes | ✅ Yes | ✅ Yes | ✅ Yes | ❌ No | ❌ No |

| Two Hammer / Two Dog | ✅ Yes | ✅ Yes | ✅ Yes | ✅ Yes | ❌ No | ✅ Yes |

| Single Pinless Hammer | ✅ Yes | ✅ Yes | ✅ Yes | ❌ No | ✅ Yes | ❌ No |

| Two Pinless Hammer | ✅ Yes | ✅ Yes | ✅ Yes | ✅ Yes | ✅ Yes | ❌ No |

Understanding these differences will help you choose the most suitable air impact wrenches for your specific needs, ensuring efficiency, longevity, and operator comfort.