Discover the benefits of Soartec’s aluminum alloy heavy duty air impact wrench. Lightweight, durable, and efficient, they are the ideal choice for professional mechanics. Explore our range of high-performance tools today!

Introduction

When choosing a heavy-duty air impact wrench, professionals require tools that deliver maximum torque, durability, and efficiency. At Soartec Tools, we engineer our air impact wrenches with high-quality aluminum alloy, ensuring superior performance and longevity.

Compared to traditional materials like cast steel or cast copper, aluminum alloy provides superior strength, corrosion resistance, and lightweight benefits. These properties make it the ideal material for heavy-duty air impact wrenches, offering users better handling, extended lifespan, and optimal energy efficiency.

In this blog, we will explore:

• Why Soartec uses aluminum alloy in our air impact wrenches

• How this material enhances performance and efficiency

• How to choose the right impact wrench for your needs

Whether you’re looking for a 3/8” air impact wrench, 3/4” air impact wrench, or 1” impact wrench, Soartec has the right tool for you.

Why Heavy Duty Air Impact Wrench Use Aluminum Alloy

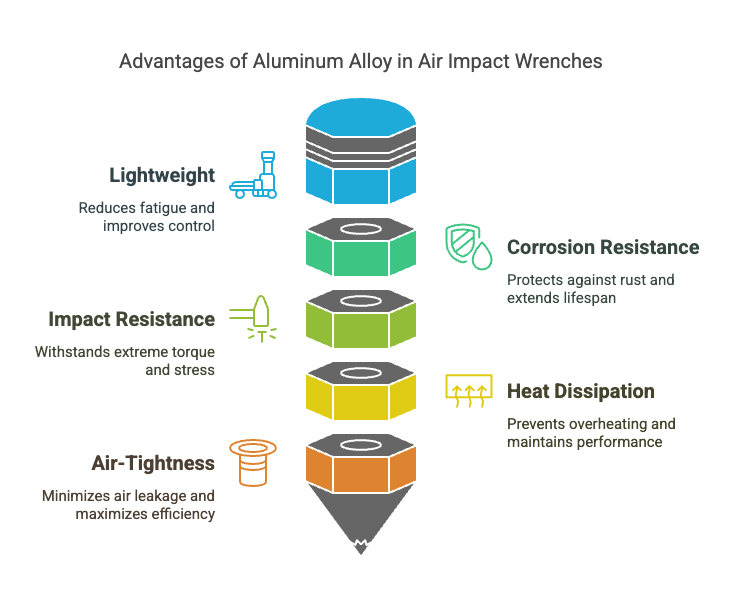

1. Lightweight for Easier Handling

Heavy duty air impact wrenches are frequently used in automotive repair, industrial maintenance, and construction. A lighter tool reduces fatigue and increases efficiency.

• Aluminum alloy significantly reduces tool weight while maintaining strength and durability.

• A lighter impact wrench improves control, maneuverability, and comfort during prolonged use.

• Less strain on the user means higher efficiency and reduced risk of injury.

If you’re working in tight spaces or need more flexibility, consider a compact 1/2” air impact wrench.

2. Superior Corrosion Resistance for Long-Term Durability

Workshops and industrial sites expose tools to moisture, oil, and harsh chemicals, which can lead to rust and corrosion.

• Aluminum alloy naturally forms an oxidation layer, protecting it from rust and wear.

• Unlike steel or iron, aluminum remains corrosion-resistant even in challenging conditions.

• This ensures a longer lifespan and reduces maintenance costs over time.

For a detailed step-by-step breakdown of impact wrench parts, check out our guide!

3. High Strength & Impact Resistance for Heavy-Duty Use

Heavy-duty air impact wrenches operate under extreme torque, placing immense stress on the tool’s housing and internal components.

• Soartec’s aluminum alloy housings provide exceptional impact resistance, making them ideal for high-torque applications.

• The structural integrity of aluminum alloy ensures long-term durability, even under continuous heavy use.

• Compared to traditional materials, aluminum withstands vibrations and mechanical stress better, preventing deformation.

Looking for the most durable 3/4” impact wrench? We’ve got you covered!

4. Better Heat Dissipation for Consistent Performance

Heavy-duty air impact wrenches generate significant heat during prolonged operation. Overheating can reduce performance and efficiency.

• Aluminum alloy has excellent thermal conductivity, allowing it to dissipate heat efficiently.

• A well-cooled impact wrench prevents overheating, power loss, and premature wear.

• This ensures consistent high performance, even under extreme workloads.

5. Enhanced Air-Tightness for Maximum Efficiency

Air impact wrenches rely on compressed air to generate torque, and any air leakage reduces efficiency.

• Soartec’s precision aluminum alloy housings provide superior air-tightness, minimizing energy waste.

• Improved sealing leads to lower air consumption, maximizing the tool’s power output.

• This means more torque per unit of compressed air, leading to better efficiency and cost savings.

Check out our guide on selecting the best 1” air impact wrench.

Best Aluminum Alloys for Heavy-Duty Air Impact Wrenches

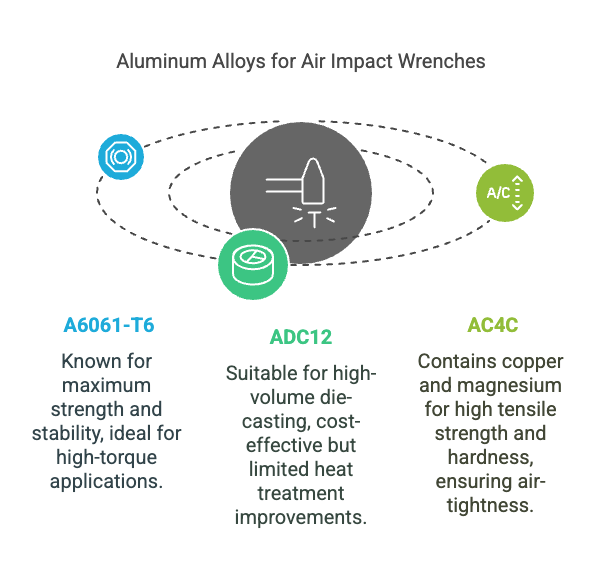

1. A6061-T6 Aluminum Alloy

• Heat-treated for maximum strength and stability.

• Provides high impact resistance, making it ideal for high-torque applications.

• Maintains superior dimensional stability over long-term use.

• Commonly used in professional-grade air impact wrenches.

2. ADC12 Aluminum Alloy

• Perfect for high-volume die-casting production.

• Forms precise and rigid components quickly

• Suitable for general-use air impact wrenches.

• Cost-effective but has limited mechanical improvements through heat treatment

3. AC4C (AA356.0) Aluminum Alloy

• Contains copper, zinc, manganese, silicon, and magnesium for increased strength.

• Heat-treated to achieve high tensile strength (150N/mm²+) and hardness (HBS 85+)

• Ensures excellent air-tightness, reducing compressed air leakage.

• Used in heavy-duty impact wrenches for maximum durability and performance.

• Longer lifespan under high air pressure work environment.

Each of these alloys is selected specifically for different types of impact wrenches, ensuring that professionals get the best performance and durability from Soartec tools.

Choosing the Right Impact Wrench for Your Needs

• Need a 3/8” impact wrench for precision tasks?

• Looking for the strongest 3/4” air impact wrench?

• Want to compare different 1” impact wrenches?

FAQ

- Why does Soartec Tools use aluminum alloy for their impact wrenches?

Soartec Tools uses AC4C aluminum alloy (AA356.0) due to its high strength, excellent fatigue resistance, and superior thermal conductivity. This alloy is specifically designed for high-stress applications, making it an ideal choice for heavy-duty air impact wrenches that operate under extreme torque and continuous use. Its durability and resistance to deformation ensure that the wrench maintains its performance and structural integrity over time, even in demanding industrial environments.

- What are the advantages of using aluminum alloy in heavy duty air impact wrench?

Aluminum alloy offers several advantages in heavy-duty air impact wrenches. It reduces tool weight, improves control, and comfort during prolonged use. It also provides superior corrosion resistance, ensuring a longer lifespan and reduced maintenance costs. Furthermore, it has excellent thermal conductivity for efficient heat dissipation and superior air-tightness for maximum efficiency.

- Why don’t composite-cased air impact wrenches last as long under high air pressure?

While composite casings offer a lighter-weight alternative, they often lack the structural rigidity needed to withstand high air pressure and prolonged heavy-duty use. Under high air pressure, composite materials may experience flexing, heat buildup, and wear at a faster rate compared to aluminum alloy casings. This can lead to reduced impact force efficiency, increased vibration, and faster material degradation. In contrast, AC4C aluminum alloy ensures better heat dissipation, structural stability, and extended tool lifespan, making it the superior choice for professional-grade impact wrenches operating at high pressures.

- What are the different types of aluminum alloys used in Soartec’s impact wrenches?

Soartec Tools uses three types of aluminum alloys in their impact wrenches: ADC12, and AC4C (AA356.0). Each of these alloys is carefully selected to enhance strength, efficiency, and longevity, ensuring that Soartec’s heavy-duty air impact wrenches exceed industry standards.

- How does the use of aluminum alloy improve the performance of Soartec’s heavy-duty air impact wrench?

The use of aluminum alloy in Soartec’s heavy-duty air impact wrenches extends tool life significantly, reduces air consumption for higher efficiency, and supports sustainability in manufacturing as aluminum is 100% recyclable. These factors contribute to reliable, consistent performance even after years of use.